On the floor of the new factory, the precise arc of an automated welding arm, guided by artificial intelligence, completes a critical seam on a block ice machine evaporator—a task once variable in quality is now executed with unerring consistency.

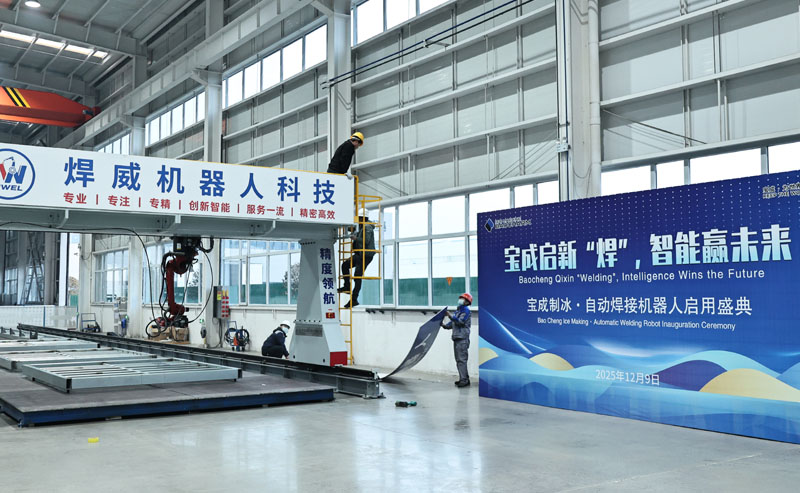

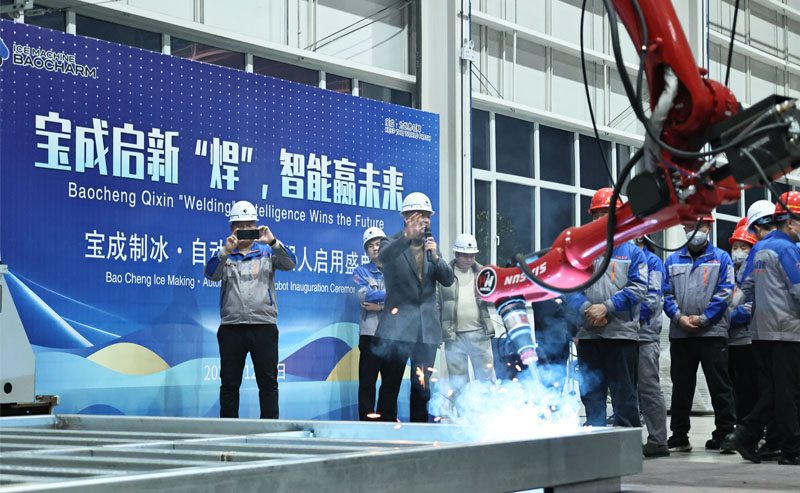

BAOCHARM, a leading ice machine manufacturer, has officially integrated advanced automated welding robots into its new 30,000+ square meter smart factory, which opened in May 2025. This strategic move marks a decisive transition from traditional manufacturing towards a fully intelligent production ecosystem.

The company, already recognized as a National High-Tech Enterprise and a key contributor to China's industrial refrigeration standards, is leveraging this technology to redefine durability, precision, and scalability in industrial ice-making equipment.

For a manufacturer of heavy-duty industrial refrigeration equipment, the quality of welding is not merely a production step; it is the foundation of product integrity. Core components like pressure vessels, compressor housings, and evaporator coils for block ice machines must withstand extreme pressures, thermal cycles, and corrosive environments over decades of continuous operation.

A single weak seam or micro-fissure can lead to costly refrigerant leaks, system failures, and significant downtime for clients in critical sectors like fisheries, food processing, and concrete cooling.

Traditionally, achieving uniform weld quality across large, complex components relied heavily on the skill and endurance of master welders. This manual process, while effective, introduced inherent variability. Factors like fatigue, visual strain, and minor environmental changes could subtly affect outcomes, making perfect consistency a persistent challenge in scaling production while upholding BAOCHARM's stringent quality standards.

The newly deployed robotic welding system represents a technological leap beyond basic automation. The equipment at BAOCHARM's facility utilizes sophisticated 3D vision and adaptive control systems.

These systems can autonomously scan a workpiece, identify the seam path, and adjust welding parameters in real-time for optimal penetration and strength.

This mirrors the "smart perception" and "precise execution" capabilities seen in other leading industrial automation upgrades, where sensors and AI work in concert to ensure flawless results.

A critical advancement is the implementation of adaptive welding technology. The robots are equipped with sensors that monitor the welding arc and pool, allowing them to compensate automatically for minor gaps, misalignments, or thermal distortion in the metal.

This ensures consistent, high-integrity welds on every unit, from a 3-ton per day block ice machine to a large-scale ice factory solution designed for 100-ton daily output.

The following table outlines the core differences between the traditional and new welding methodologies:

| Feature | Traditional Manual Welding | New Automated Robotic Welding |

| Consistency & Quality | Subject to human skill and variability | AI-driven, with real-time parameter adjustment for uniform, X-ray grade welds |

| Production Efficiency | Limited by welder speed and stamina | Uninterrupted, high-speed operation, significantly shortening unit production cycles |

| Process Adaptation | Requires manual reprogramming for new components | Features vision-based "automatic programming" for smooth changeovers |

| Data & Traceability | Limited manual logs | Every weld is digitally recorded, creating a full quality traceability log |

| Working Environment | Ergonomic strain, exposure to fumes, and arc flash | Removes personnel from hazardous tasks, enhancing safety |

The integration of this smart welding technology directly translates into tangible benefits across BAOCHARM's manufacturing pipeline and the value delivered to its global clientele. The most immediate impact is on production efficiency and capacity.

The new factory, now powered by these automated systems, can achieve a significantly higher and more predictable output. This enhanced capacity is crucial for meeting the growing global demand for reliable ice making machines.

For end-users, the benefit is embedded in the product itself. Equipment with welds of uncompromising integrity translates directly into longer operational lifespans, reduced risk of unscheduled maintenance, and lower total cost of ownership.

Whether it's a seafood processor relying on a steady supply of ice or a chemical plant using a industrial ice maker machine for process cooling, BAOCHARM's clients gain equipment built to perform under pressure, year after year.

This upgrade solidifies BAOCHARM's position not just as an equipment seller, but as a provider of comprehensive, high-reliability ice factory solutions.

The adoption of automated welding is not an isolated upgrade but a keystone initiative in BAOCHARM's broader vision for intelligent manufacturing. The new smart factory is designed as an integrated ecosystem.

The robotic welding cells feed production data into a central manufacturing execution system (MES). This system, akin to the digital twin technology employed by other advanced manufacturers, creates a virtual model of the production process.

This allows for unprecedented oversight, predictive maintenance of the manufacturing equipment itself, and continuous optimization of the entire production flow.

This forward-looking strategy ensures that BAOCHARM's innovation extends beyond the product to encompass the entire customer journey. From initial design consultation to remote monitoring of installed ice making machines, the company is building a connected service framework.

This positions BAOCHARM to lead in the next generation of industrial cooling, where equipment intelligence and manufacturing excellence are inseparable.

BAOCHARM's investment in automated robotic welding transcends a simple equipment purchase. It represents a fundamental commitment to engineering excellence and customer-centric innovation. By mastering the microscopic details of a welding seam, the company guarantees the macroscopic performance of its entire product line.

This move from skilled craftsmanship to precision-engineered consistency ensures that every industrial ice machine or industrial cooling solution leaving the new factory carries a built-in promise of reliability, efficiency, and longevity.

For industries where cooling is not a convenience but a critical operational pillar, the stakes for equipment failure are high. BAOCHARM's manufacturing evolution directly addresses this, transforming potential vulnerabilities into unshakeable strengths.

The future of industrial ice production is being written in the code of robots and the data from sensors, and BAOCHARM's new smart factory is poised at the forefront of this transformation.

Why risk downtime with variable quality? Partner with a manufacturer where every weld is guaranteed by data-driven automation. Explore our range of reliable ice making equipment designed for critical applications. Speak with a Specialist About Your Needs!

Our Contacts

Email: sales@baocharm.com

WhatsApp: +86 17663537579

Wechat: +86 17663537579

Working Hours: Mon ~ Sat 8:30 AM - 5:30 PM