February 11, 2026

February 11, 2026

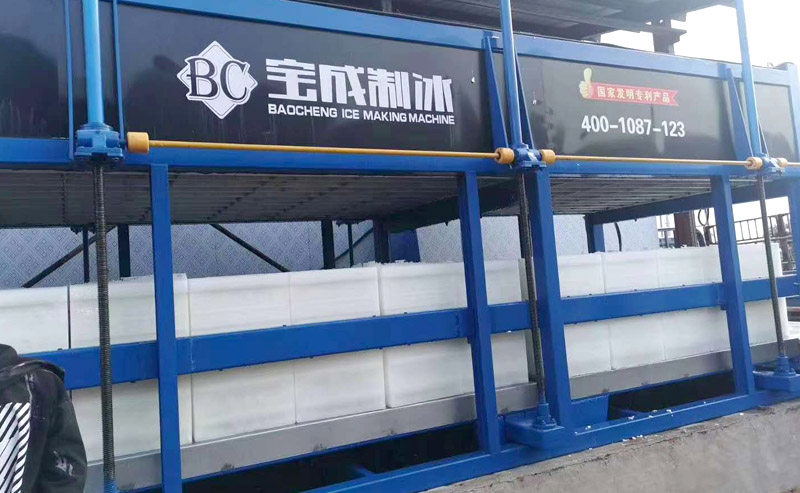

In the industrial ice production industry, the transition from traditional brine ice systems to modern direct cooling ice block making machine technology represents a significant leap forward in efficiency, hygiene, and operational cost savings. As many facilities still rely on older brine ice making technology, understanding the upgrade process has become essential for maintaining competitiveness. This guide provides a comprehensive analysis of both systems and a detailed roadmap for a successful transition.

Traditional brine ice making systems have been the workhorses of industrial ice production for decades. These systems operate on an indirect cooling principle where a saltwater solution acts as a heat exchange medium. The brine is cooled by refrigeration equipment, and this chilled brine then circulates around ice molds to freeze water into blocks.

Despite these limitations, brine ice systems maintain a significant market presence, particularly in older facilities and regions where initial cost outweighs long-term efficiency considerations. However, the industry trend is clearly moving toward direct cooling block ice making technology as the new standard for industrial ice production.

When evaluating ice making plant solutions, understanding the technological differences between these systems is crucial for making informed decisions.

Table: Comparative Analysis of Ice Making Systems

| Feature | Brine Ice System | Direct Cooling System |

| Cooling Method | Indirect (brine medium) | Direct (refrigerrant to water) |

| Freezing Time | Slower | 30-50% faster |

| Energy Consumption | Higher | Significant savings |

| Hygiene | Requires post-production washing | Food-grade ice directly |

| Automation Level | Manual harvesting | Fully automated process |

| Space Requirements | Large footprint | Compact, modular design |

| Water Usage | Higher | Optimized consumption |

| Initial Investment | Lower | Higher but with better ROI |

The direct cooling 10 tons ice block making machine offers distinct advantages in operational efficiency and ice quality. By using aluminum plates as evaporators that directly contact the water, these systems achieve faster freezing times and produce hygienic ice that doesn't require additional washing.

Transitioning from saltwater to direct cooling technology requires careful planning and execution. Here's what you need to consider:

Return on Investment: Most facilities report an ROI period of 2-3 years based on energy savings alone, with additional benefits in reduced maintenance and improved production reliability.

A phased transition approach minimizes disruption to your ice supply operations:

Ice Quality Compatibility: Direct cooling systems produce 25kg block ice making machine output (and other sizes) that is chemically compatible with ice produced from brine ice making systems, ensuring no disruption to your clients' operations.

Converting your facility requires a methodical approach:

The transition from traditional brine ice making systems to modern direct cooling ice block making machine technology represents a significant step forward in industrial ice production. With advantages in energy efficiency, operational hygiene, automation, and space utilization, direct cooling systems offer a compelling value proposition despite the higher initial investment.

The upgrade process requires careful planning and execution, but the long-term benefits substantially outweigh the transition challenges. By following a structured approach to implementation, facilities can minimize disruption while positioning themselves for greater operational efficiency and profitability.

Ready to modernize your ice production facility? Our experts specialize in transitioning operations from traditional brine ice making systems to high-efficiency direct cooling ice block making machine technology. We provide:

Contact us today for a complimentary feasibility study and transition plan tailored to your specific operation requirements and production goals. Our technical team will enhance the value of your ice-making industry with professional services.

Our Contacts

Email: sales@baocharm.com

WhatsApp: +86 17663537579

Wechat: +86 17663537579

Working Hours: Mon ~ Sat 8:30 AM - 5:30 PM