Industrial Block Ice Machine Investment Guide: Key Costs for Your Block Ice Factory Project

February 20, 2025

Investing in a block ice factory is a strategic decision that requires meticulous planning, particularly in understanding upfront costs. This guide breaks down the essential expenses—from equipment procurement to operational overheads—to help you make informed financial decisions for your industrial ice production venture.

Core Equipment Costs: Industrial Ice Block Making Machines

The heart of your block ice factory is the industrial ice block making machine. Prices vary significantly based on:

- Production Capacity: Machines producing 5-20 tons daily range from $30,000 to $150,000.

- Block Size: Customizable dimensions (e.g., 2.5kg to 100kg blocks) may increase costs.

- Automation Level: Fully automated systems reduce labor but raise initial investment.

- Auxiliary Equipment: Conveyor systems, cold storage installation, and ice crushers add 15-30% to the base machine cost.

Pro Tip: Opt for modular designs to scale production as demand grows.

Installation & Commissioning Expenses

Proper ice machine installation ensures efficiency and longevity. Key costs include:

- Infrastructure Setup: Electrical wiring, water pipelines, and insulation for cold storage installation.

- Technical Support: Hiring experts for calibration and safety checks (Refer to local labor costs).

- Compliance Fees: Permits or certifications for industrial equipment operation.

Note: Poor installation can lead to higher energy consumption.

Operational Costs: Long-Term Financial Considerations

Daily expenses directly impact profitability:

- Energy Consumption: Calculate electricity costs based on machine specs (e.g., 60 kWh per ton of ice).

- Maintenance: Budget 3-5% of equipment cost annually for parts like compressors or evaporators.

- Labor: Automated systems reduce staffing needs, but skilled technicians may cost $20–$40/hour.

- Water Supply: High-purity water treatment systems prevent scaling and downtime.

Ancillary Expenses for Ice Factory Projects

- Space Requirements: Rent or purchase costs for facilities with adequate power/water access.

- Insurance: Protect against equipment breakdowns or natural disasters ($1,000–$3,000/year).

- Tax Incentives: Research local policies for manufacturing or energy-efficient equipment rebates.

Laying the Foundation for ROI

Understanding these costs is the first step toward a profitable block ice factory. While initial investments may seem daunting, strategic planning minimizes risks and maximizes efficiency.

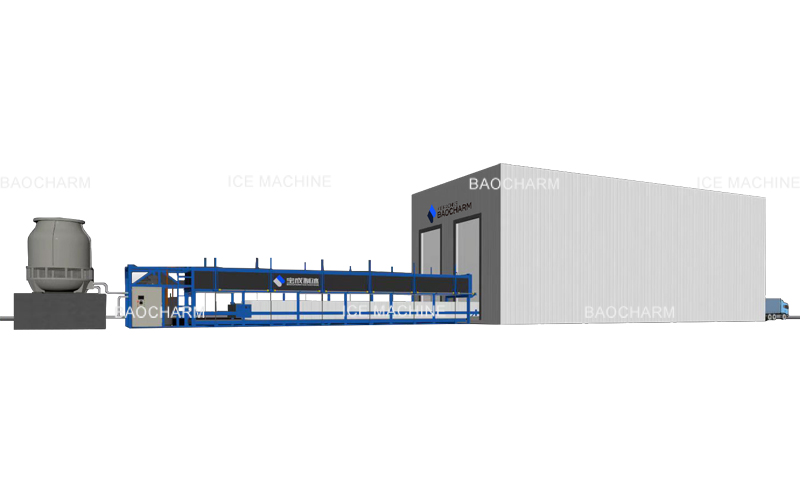

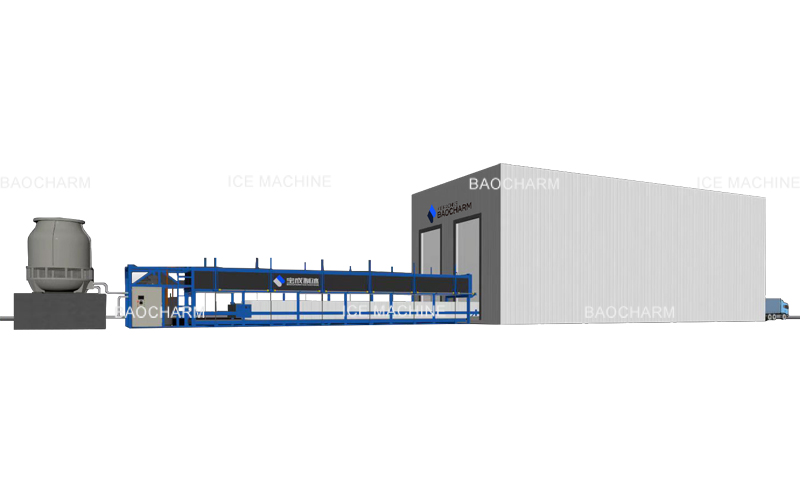

Optimize Your Ice Factory Investment with Expert Support

At BAOCHARM, we specialize in turnkey solutions for industrial ice production—from machine selection to cold storage installation. Contact our team today for a customized cost analysis or equipment quote. Let’s build your competitive edge together!

Ready to Calculate Your Returns?

Explore our next guide: Maximizing ROI with Industrial Big Block Ice Maker Machines: A Comprehensive Return on Investment Analysis

February 11, 2026

February 11, 2026