February 11, 2026

February 11, 2026

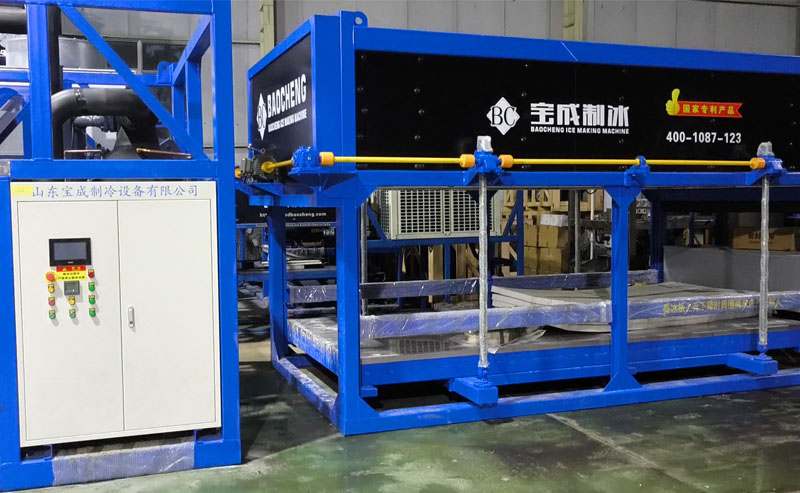

Energy efficiency is a cornerstone of modern industrial operations. For businesses relying on industrial ice block machines, conducting an energy audit is an indispensable step to achieve optimal performance while minimizing energy consumption. This process not only reduces operational costs but also aligns with sustainability goals. In this article, we explore the value of energy audits in enhancing the performance of industrial ice block machines and share practical insights from BAOCHARM’s industry-leading practices.

Energy audits are systematic evaluations of energy use in industrial equipment. In the context of ice block machines, these audits help identify inefficiencies, measure energy consumption patterns, and suggest actionable improvements. By leveraging data-driven insights, businesses can pinpoint areas for optimization, ensuring that their machines deliver consistent performance under varying conditions.

Industrial ice block machines, especially those using direct cooling technology, operate under demanding conditions. Regular audits can identify latent inefficiencies, such as unnecessary energy losses, outdated components, or improper operational settings. Addressing these inefficiencies enhances productivity and prolongs equipment lifespan.

Measure the current energy consumption of your industrial ice block machine. Tools like energy meters and software analytics can help track usage over a defined period, capturing data on electricity consumption, machine output, and environmental conditions.

Analyze energy data to detect anomalies, such as excessive power usage during non-peak production hours or underutilization of capacity. Components like compressors, evaporators, and condensers should be inspected for wear and tear or inefficiency.

Compare your machine’s energy performance to industry standards. For example, a highly efficient direct cooling ice block machine should consume between 55 to 60 kWh per ton of ice at ambient temperatures of 30-35°C. Deviations from this benchmark indicate opportunities for improvement.

At BAOCHARM, we’ve harnessed decades of expertise in industrial ice block machine production to create solutions that set the standard for energy efficiency. Our energy audits have directly led to significant cost savings and enhanced machine reliability for our clients.

For instance:

Energy audits not only enhance machine performance but also address unique industry requirements. For sectors like seafood processing, construction, and pharmaceuticals, reliable and energy-efficient ice production is vital. Customized energy optimization ensures uninterrupted operations while cutting costs.

BAOCHARM stands out as a trusted partner in the industrial ice machine sector. Our energy-efficient solutions and commitment to innovation ensure that your business stays ahead of the curve. Whether you need an automatic ice tube maker machine or industrial ice-making equipment tailored to your needs, we provide expert guidance and state-of-the-art technology.

Maximize the performance of your industrial ice block machines with a comprehensive energy audit. Contact BAOCHARM today to schedule a consultation and learn how we can help your business save energy, reduce costs, and achieve operational excellence.

Contact Us Now to begin your journey toward a more sustainable and cost-efficient future.

Our Contacts

Email: sales@baocharm.com

WhatsApp: +86 17663537579

Wechat: +86 17663537579

Working Hours: Mon ~ Sat 8:30 AM - 5:30 PM