Understanding Water Quality Requirements for Direct Cooling Ice Block Machines

June 23, 2025

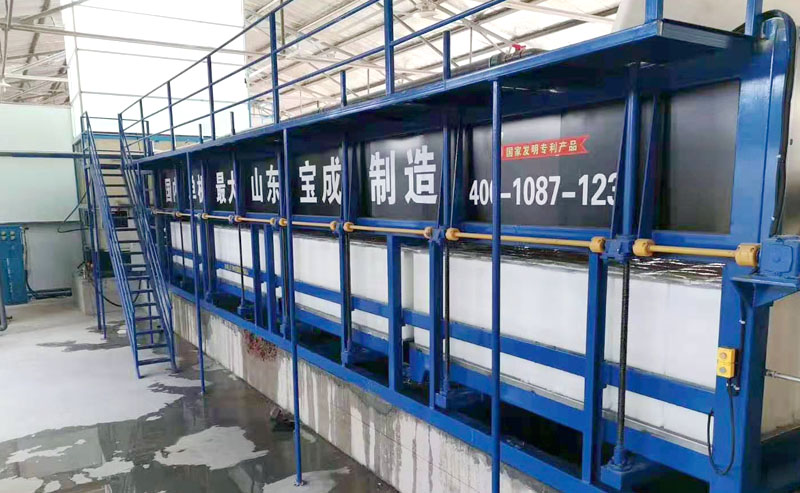

Water isn't just an ingredient in ice production; it's the lifeblood of your direct cooling ice block machine. Ignoring its quality risks costly downtime, compromised ice purity, and shortened equipment lifespan. Whether you operate a block ice factory or manage ice factory machine plant making, understanding these requirements is fundamental to your ice making business success.

Foundational Water Quality Parameters

The core physical/chemical properties of your source water directly impact ice clarity, production speed, and system health:

- Hardness Control (CaCO3): Must typically stay below 50-100 ppm. High hardness causes rapid scale buildup on evaporator plates and condenser tubes, drastically reducing heat transfer efficiency in water cooled ice machine systems.

- pH Range: Maintain between 6.5 and 8.5. Water that's too acidic corrodes metal components; alkaline water accelerates scaling.

- Suspended Solids & Particulates: Must be minimized (< 5 ppm). Sand, silt, and rust clog valves, filters, and spray nozzles, impacting even robust 10 tons large ice block maker machine units.

Ensuring Ice Purity: Sanitary & Microbial Standards

Safe, consumable ice demands strict biological and chemical control:

- Microbiological Limits: Total coliforms must be absent. Regular testing for bacteria, molds, and yeasts is non-negotiable to prevent contamination.

- Heavy Metals & Organics: Lead, mercury, pesticides, and volatile organic compounds (VOCs) must meet drinking water standards (e.g., EPA, WHO). These affect ice taste, odor, and safety.

Adapting to Challenging Water Sources

Specialized pretreatment becomes crucial for non-ideal water conditions:

- High Hardness Water: Requires robust water softening systems (ion exchange) or antiscalant chemical dosing upstream of the direct cooling ice block machine.

- High Salinity/Brackish Water: Demands reverse osmosis (RO) systems to remove dissolved salts that cause corrosion and affect freezing point.

- Low Temperature Supply Water (<10°C/50°F): Can slow initial freezing. Systems may need adjustment or pre-heating (if feasible) for optimal 10 tons large ice block maker machine efficiency.

Proactive Water Quality Maintenance

Prevention is far cheaper than repairs:

- Pre-treatment Systems: Essential investments include sediment filters, water softeners, carbon filters, and potentially RO systems – tailored to your specific water analysis.

- Monitoring Schedule:

- Daily/Weekly: Visual checks for turbidity, basic TDS meter readings.

- Monthly: Hardness, pH, chlorine residual tests.

- Quarterly: Full chemical panel & microbiological testing by certified labs.

- Deep Maintenance: Annual descaling of evaporators and condensers (even with soft water), sanitization of water tanks and distribution lines.

Responding to Water Quality Issues

Act swiftly when problems arise:

- Scale Buildup Emergency: Use approved food-grade descaling solutions circulated through the system. Never use harsh acids without expert guidance. Investigate and enhance pretreatment immediately.

- Microbial Contamination: Immediately halt production. Shock-sanitize the entire water system (tanks, pipes, machine). Replace filters. Identify and eliminate the contamination source before restarting.

Conclusion

Water quality is not an afterthought; it's a core operational parameter for efficient and hygienic ice production using direct cooling ice block machine technology. From small ice making business ventures to large-scale block ice factory operations, neglecting water leads to increased costs, unsafe ice, and premature equipment failure. Implementing a rigorous water management program – encompassing pretreatment, monitoring, and maintenance – is essential for protecting your investment and ensuring your ice meets the highest standards.

Optimize Your Ice Production Today!

Does your source water meet the stringent demands of a high-output 10 tons large ice block maker machine? Ensure your ice factory machine plant making runs at peak efficiency and produces crystal-clear, safe ice blocks. Contact us today for a FREE water analysis consultation and customized pretreatment solution!

February 11, 2026

February 11, 2026