Exploring Durability and Sustainability in Industrial Ice Making Machines: The Role of Material Science

Dec 17, 2024

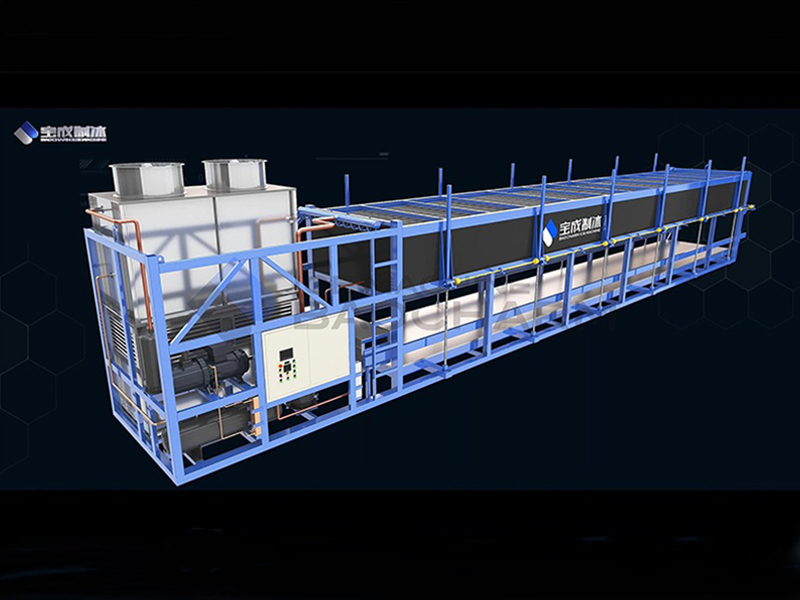

In the competitive world of industrial ice production, the durability and sustainability of ice making machines are paramount to their overall performance and long-term value. Whether it's for large-scale food preservation, pharmaceutical applications, or industrial cooling, the materials used in ice machines directly impact their operational efficiency, lifespan, and environmental footprint. As businesses demand higher capacity, energy efficiency, and longer-lasting solutions, understanding the role of material science in the design and manufacture of industrial ice makers has become increasingly important.

At BAOCHARM, we recognize that the success of an ice machine is not only determined by its ice production capabilities but also by the durability of the materials that make up the machine. This article delves into how material selection influences the lifecycle of industrial ice machines, focusing on key components like ice block maker machines, tube ice maker machines, and large capacity ice machines.

The Role of Materials in Ice Making Machines

Industrial ice making machines are designed to withstand continuous operation in demanding environments. The materials used in constructing these machines must balance strength, resistance to wear and tear, and corrosion protection. The most common materials employed include stainless steel, aluminum alloys, and other metal composites, each offering distinct advantages in terms of durability and performance.

Stainless Steel: The Gold Standard for Durability

Stainless steel is a primary material in industrial ice making machines, especially for parts that are exposed to water, ice, and fluctuating temperatures. Its corrosion-resistant properties make it ideal for stainless steel ice maker machines, ensuring long-term durability even in harsh conditions. This material's ability to resist rust and oxidation significantly extends the machine’s operational life, making it particularly suitable for heavy-duty applications, such as large capacity ice machines.

Furthermore, stainless steel is known for its excellent thermal conductivity, enhancing the efficiency of the ice-making process. It ensures that the machine operates smoothly without the risk of material degradation, which is a common issue in machines exposed to constant moisture.

Aluminum Alloys: Lightweight and Efficient

While stainless steel dominates many ice maker components, aluminum alloys are also gaining popularity, particularly for machine frames and some internal parts. Aluminum is lighter than stainless steel, which can help reduce the overall weight of machines, particularly important for heavy duty ice machines that require frequent mobility or relocation.

The key benefit of aluminum alloys is their excellent resistance to corrosion, particularly when anodized or treated with protective coatings. Aluminum's lightness and high strength-to-weight ratio make it ideal for tube ice maker machines, which require robust yet manageable structures.

Other Materials: Enhancing Specific Features

Other materials such as copper, nickel, and titanium are sometimes used in specialized components like ice-making coils or refrigerant systems. Copper, for example, has superior heat transfer properties, which can enhance the cooling and ice-making speed. However, it's less commonly used due to its susceptibility to corrosion compared to stainless steel.

BAOCHARM’s Approach to Material Science in Ice Machine Durability

At BAOCHARM, we understand that choosing the right materials is not just about performance but also about ensuring sustainability. As the world becomes more conscious of environmental impact, we’ve made significant strides in integrating materials that not only enhance the durability of our machines but also contribute to sustainability.

Our research and development team works tirelessly to test new materials and manufacturing techniques that improve both the efficiency and eco-friendliness of our ice machines. For example, we focus on minimizing the carbon footprint during production and exploring recyclable materials for parts that may eventually need replacement or disposal. This process is integral to our long-term vision of reducing the environmental impact of our ice machines, from ice block maker machines to large capacity ice machines.

We also prioritize energy-efficient designs that rely on the durability of our materials to reduce the need for frequent repairs and replacements, ultimately lowering the machine’s total environmental footprint. Through continuous innovation, we are able to deliver ice machines that meet the rigorous demands of our customers while contributing to a more sustainable future.

The Impact of Material Choices on Machine Lifecycle and End-of-Life Recycling

As industrial ice makers become more advanced, there is an increasing focus on the end-of-life phase of the machine. How can these machines be recycled or responsibly disposed of when they reach the end of their useful life?

By using recyclable materials such as stainless steel and aluminum, BAOCHARM ensures that a significant portion of each machine can be reused in future manufacturing processes. This practice reduces waste and ensures that valuable resources are not discarded unnecessarily.

Furthermore, BAOCHARM is actively working on implementing better disassembly techniques that will allow easy separation of materials for efficient recycling. This proactive approach to material selection and recycling aligns with our commitment to sustainability and minimizing environmental impact.

Conclusion

Material science plays a crucial role in the design, durability, and sustainability of industrial ice making machines. At BAOCHARM, we understand that the materials used in our ice maker machines directly affect their performance, longevity, and eco-friendliness. By choosing high-quality materials such as stainless steel and aluminum alloys, we ensure that our heavy duty ice machines, tube ice maker machines, and large capacity ice machines provide optimal performance while reducing their environmental footprint.

If you’re interested in learning more about how material science influences the durability and sustainability of industrial ice makers or have specific inquiries about our products, don’t hesitate to contact us. We’re here to provide expert advice and help you choose the best solutions for your business.

Read More