Industrial Tube Ice Machine: Evolution, Applications, and Key Insights

April 16, 2025

Industrial tube ice machines are specialized refrigeration systems designed to produce cylindrical, hollow ice tubes. These machines play a vital role in industries requiring high-purity ice for cooling, preservation, and processing. In this article, we delve into the fundamentals of tube ice machines, their historical development, applications, and critical considerations for businesses.

What Is an Industrial Tube Ice Machine?

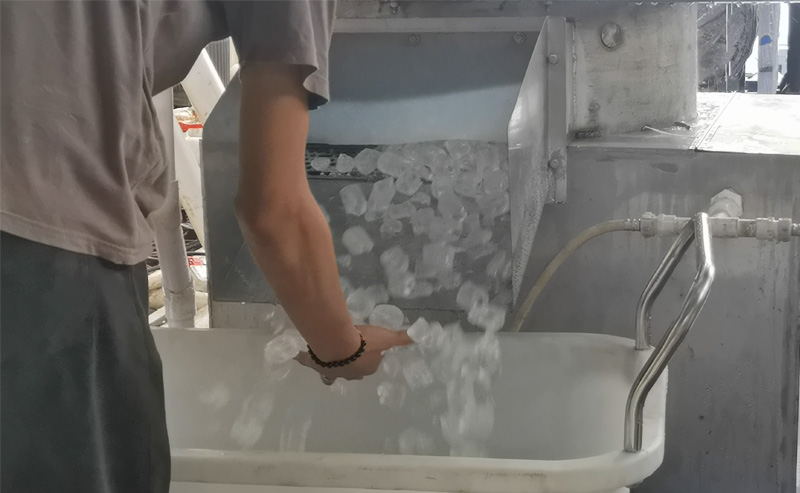

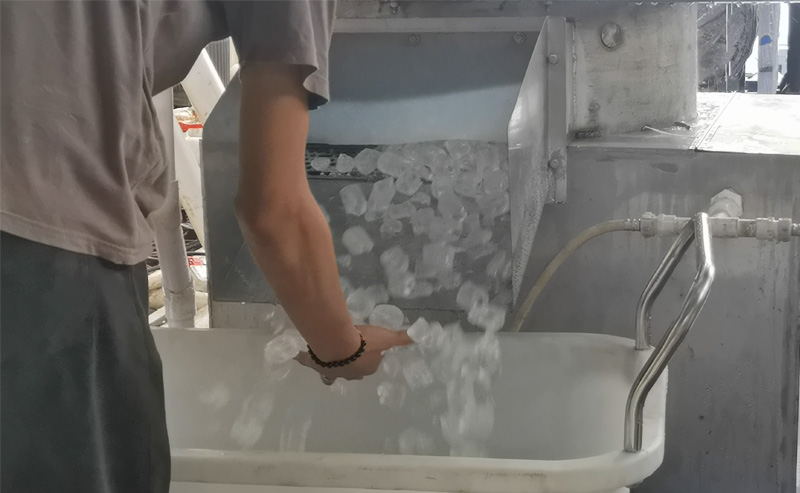

A tube ice machine is a refrigeration unit that generates cylindrical ice tubes by freezing water inside vertical stainless steel tubes. The ice produced is hygienic, melts slower than conventional ice types, and is ideal for prolonged cooling. Modern tube ice machines integrate automation, energy efficiency, and scalability to meet diverse industrial demands.

The Evolution of Tube Ice Machines

Early Innovations (1930s–1960s)

- The concept of tube ice production emerged alongside advancements in refrigeration technology. Early models were manually operated and limited to small-scale applications.

Commercial Adoption (1970s–1990s)

- Improved automation and stainless-steel materials enhanced reliability. Industries like fisheries and food processing began adopting tube ice systems for bulk ice needs.

Modern Advancements (2000s–Present)

- Energy-efficient compressors, IoT-enabled monitoring, and eco-friendly refrigerants now define next-gen tube ice plants. These innovations reduce operational costs and environmental impact.

Key Applications of Tube Ice

Food & Beverage Industry

- Used to chill seafood, meat, and dairy products during processing and transport.

Chemical & Pharmaceutical Sectors

- Maintains precise temperatures in chemical reactions or vaccine storage.

Fisheries & Agriculture

- Preserves freshness in fish farms and hydroponic systems.

Concrete Cooling

- Controls temperature in large-scale concrete mixing to prevent cracks.

Advantages of Tube Ice Machines Over Competing Ice Systems

- Efficiency: Produces ice faster (24–48 hours for full capacity) compared to block ice machines.

- Hygiene: Closed-loop water systems minimize contamination risks.

- Durability: Ice tubes withstand longer storage and transport without melting.

- Cost-Effectiveness: Lower energy consumption per ton of ice produced.

Expanding Your Ice Tube Business: Key Considerations

Selecting a Reliable Tube Ice Supplier

- Partner with certified manufacturers offering warranties, spare parts, and technical support.

Machine Customization

- Opt for modular designs to scale production as demand grows.

Maintenance Best Practices

- Regularly clean evaporators and condensers.

- Monitor refrigerant levels and compressor performance.

- Train staff on safety protocols.

Industrial tube ice maker machines are indispensable for industries requiring efficient, hygienic, and long-lasting cooling solutions. From their early mechanical designs to today’s smart, eco-conscious systems, these machines continue to evolve to meet global demands.

Ready to Optimize Your Ice Production?

As a leading tube ice supplier, Baocharm offers state-of-the-art tube ice making machines tailored to your business needs. Contact us today to request a quote or learn how our tube ice plants can elevate your operations. Let’s build your ice tube business together!

February 11, 2026

February 11, 2026